|

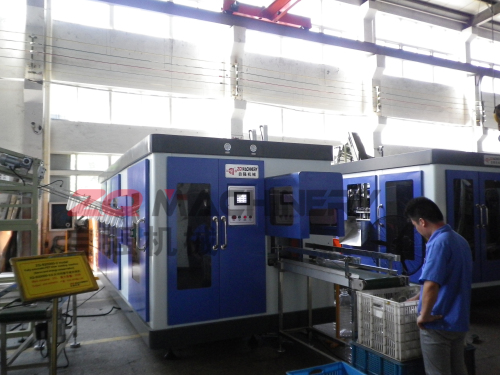

Zhejiang East Zhouqiang Plastic & Mould Industry Co., Ltd.(ZQ Machinery)

|

plastic bottle stretch moulding machine

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

| View the Video: |

|

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

plastic bottle stretch moulding machine

1.High speed:2800-3300bph,<=2000ML.

2.Easy installation and starting.

plastic bottle stretch moulding machine

ZQ-B series full-automatic pet stretch blow molding machine is the most stable two-step automatic stretch blow moulding machine. It has one to six cavities and the maximum capacity of the products is 0.6L,2.0L,5L and 10L. It can blow bottles in shapes: carbonated, mineral, pesticide, cosmetics, wide-mouth, hot filling, and other packing containers, which is made of plastic of crystalline type, such as PET and PP etc.

Settings

a).PLC colour display: OMRON(JAPAN)

b).Pneumatic parts:FESTO(GERMANY)

c).Controller of preform transfer:Servo motor DELTA(TAIWAN)

d).Other electric parts are all world-famous brand

Advantages

1).High Automatization

2).High Intelligence:The machine can be controlled through touch screen and running status is shown on it.

3).High Quanlity:Steady infrared heating system blowing and highly precise blow-mould closing system ensure quality.

4).High Speed:1400BPH(1-cavity) 8000BPH(6-cavity).

5).No Contamination:Closed production zone, good self-lubrication system avoid contamination.

6).Low Cost:Low consumption of electricity, air and water.

7).High Transparency:Easy maintenance, absolute safely, visual inspection, low noise.

plastic bottle stretch moulding machine

| TYPE | ITEM | ZQ-B1500-2 | ZQ-B1500-3 | ZQ-B1500-4 | ZQ-B1500-6 |

| CONTAINER | Number of cavity | 2 cavities | 3 cavities | 4 cavities | 6 cavities |

| Output | 2400-2600 pcs/hr | 2800-3300 pcs/hr | 3800-4200 pcs/hr | 5500-6000 pcs/hr | |

| Max.container volume | 2.0L | 2.0L | 2.0L | 2.0L | |

| Max.neck diameter | 38mm | 38mm | 38mm | 38mm | |

| Max.container diameter | 105mm | 105mm | 105mm | 105mm | |

| Max.container height | 300-330mm | 300-330mm | 300-330mm | 300-330mm | |

| ELECTRICAL SYSTEM | Number of lamp | 27pcs | 36pcs | 60pcs | 90pcs |

| Max.heating power | 27kw | 36kw | 60kw | 90kw | |

| Installation power | 38kw | 48kw | 65kw | 96kw | |

| Actual power consumption | 18kw | 22kw | 40kw | 60-70kw | |

| AIR SYSTEM | Operatating pressure | 7-9kg/cm² | 7-9kg/cm² | 7-9kg/cm² | 7-9kg/cm² |

| Low pressure consuming | 1200Ltr/min | 1400Ltr/min | 2000Ltr/min | 3000Ltr/min | |

| Blowing pressure | 25-35kg/cm² | 25-35kg/cm² | 25-35kg/cm² | 25-35kg/cm² | |

| High pressure consuming | 2000-2500 Ltr/min | 2000-3000 Ltr/min | 3000-3500 Ltr/min | 4500-5000 Ltr/min | |

| CHILLER WATER | Operating pressure | 5-6 kg/cm² | 5-6 kg/cm² | 5-6 kg/cm² | 5-6 kg/cm² |

| Temperatuer | 10ºC | 10ºC | 10ºC | 10ºC | |

| Consuming | 5600kcal/hr | 7600kcal/hr | 19000 kcal/hr | 25200 kcal/hr | |

| Flow rater | 30Ltr/min | 45Ltr/min | 60Ltr/min | 200Ltr/min | |

| MACHINE | Machine dimension | 3.25x1.5x2.1(m) | 4.5x2.1x2.1(m) | 4.7x2.1x2.1(m) | 7.3x2.2x2.1(m) |

| Machine weight | 3.1ton | 3.9ton | 4.1ton | 6.35ton |

Note: The specifications are subject to change without notice for the further improvement.

plastic beverage bottles pet stretch blow molding machinery

.jpg)